Danke für Ihr Interesse an den Lernpräferenzen!

Danke für dein Interesse an verschiedenen Lernmethoden! Welche Methode bevorzugst du? (z. B. „Audio“, „Video“, „Text“, „Keine Präferenz“) (optional)

Feedback sendenKnetmaschine Definition

A Knetmaschine, or kneading machine, is an essential piece of equipment in bakeries and various culinary settings. This machine is primarily used to handle dough, making the process efficient and consistent. It automates the labor-intensive task of kneading, ensuring uniform texture and elasticity in the dough. Understanding its function and application is crucial for anyone pursuing a career in gastronomy or tourism.

What is a Knetmaschine?

A Knetmaschine is a mechanical device designed to knead, mix, and blend dough ingredients. It typically consists of a bowl, a motor, and attachments such as hooks or beaters that mimic the movement of hands kneading dough.

- Bowl: The bowl holds the ingredients during the mixing process. It is usually made of stainless steel to ensure durability and hygiene.

- Motor: The motor drives the movement of attachments, varying in speed to control the kneading intensity.

- Attachments: These include dough hooks and beaters that rotate or spiral to mimic traditional kneading motions.

In a bakery, a Knetmaschine can knead up to 50 kilograms of dough in one batch, showcasing its efficiency compared to manual kneading.

The evolution of the Knetmaschine from manual dough kneading tools illustrates the advances in culinary technology. Initially, bakers relied on hand-kneading, which was physically demanding and inconsistent. The introduction of Knetmaschinen revolutionized the baking industry by offering a more reliable and faster method. Modern machines now come with programmable settings that allow bakers to set specific kneading times, speeds, and rest periods automatically, tailoring the dough-making process to different recipes and improving precision.

When selecting a Knetmaschine, consider the machine's capacity and the type of dough typically prepared to ensure compatibility.

Knetmaschine Technik

The technology behind a Knetmaschine is crucial for ensuring consistent results in culinary tasks. These machines are designed to replicate and enhance the traditional kneading process through advanced mechanical parts and design. Understanding how these machines operate can help you utilize them effectively in various gastronomic settings.

Mechanics of a Knetmaschine

Knetmaschinen rely on a combination of mechanical efficiency and design to perform their function:

- Motor Power: Usually varies between 0.5 to 2 horsepower, allowing for different speeds and kneading intensities.

- Speed Settings: Multi-speed settings offer flexibility and control over the dough consistency.

- Dough Hook Design: Spiral or ‘C’ shape hooks ensure thorough mixing and aeration of the dough.

- Programmable Timers: Allow precision and consistency by setting kneading times.

A bakery using a Knetmaschine can adjust its speed settings to accommodate dense dough for bread or lighter settings for pastries, optimizing the final product's texture.

Exploring the engineering behind Knetmaschinen reveals the intricate balance of mechanics and simplicity. The integration of electronic controls in advanced models has optimized performance significantly. Electronic sensors monitor dough consistency and adjust the motor speed automatically. Additionally, modern machines might include cooling systems to prevent motor overheating during extended periods of use. Such innovations underline the importance of adapting technology to improve traditional culinary techniques.

Regular maintenance of the motor and attachments can extend the lifespan of a Knetmaschine and ensure optimal performance.

Teig Knetmaschine für Brotteig

In the culinary world, especially in bakeries, the production of bread requires consistent and high-quality dough. A Knetmaschine designed for brotteig, or bread dough, plays a crucial role in achieving this consistency. These machines streamline the kneading process, ensuring that bread dough is mixed evenly and efficiently, which is essential for achieving the desired texture and flavor in bread products.

How a Knetmaschine Assists in Bread Making

- Efficiency: The machine handles large quantities of dough at once, which is especially beneficial in commercial baking settings.

- Consistency: Ensures that every batch of dough is kneaded to the same standard, reducing variability in the final product.

- Time-Saving: Reduces manual labor, allowing bakers to focus on other tasks, increasing overall productivity.

Imagine a bakery that needs to prepare dozens of loaves each morning. The use of a Knetmaschine enables the bakery to produce uniformly kneaded dough, helping to maintain the quality and consistency expected by customers.

The historical evolution of bread-making machines, such as the Knetmaschine, highlights significant advancements in technology. Before these machines, bakers relied solely on manual kneading, which was time-consuming and physically exhaustive. Modern Knetmaschinen use sophisticated technology that allows for programmable settings, offering precision in kneading and achieving the perfect bread texture. For instance, some machines can simulate different traditional kneading techniques, adapting to specific dough requirements and recipes. This innovation reflects growing trends in the food industry towards automation and efficiency, enabling smaller bakeries to compete with large-scale production by maintaining high standards of craftsmanship.

For improved flavor and texture in bread dough, consider allowing the dough to rest after being kneaded by the Knetmaschine, a process known as autolyse.

Knetmaschine Bedienung

The operation of a Knetmaschine is pivotal for effective dough preparation in gastronomy settings. Understanding its use ensures maximum efficiency and product quality, tailored specifically for use in bakeries and culinary schools.

Knetmaschine in der Gastronomie

Knetmaschinen are indispensable in the gastronomic industry, providing solutions for large-scale dough preparation. Here's how they are primarily utilized within the industry:

- Ensures uniform mixing of ingredients to maintain consistent dough quality.

- Reduces the manual labor required for kneading, allowing staff to allocate time to other tasks.

- Allows for precise control over kneading time and speed due to programmable settings.

A Knetmaschine is an essential tool in professional kitchens, used primarily to mix and knead dough ingredients, optimizing the texture and elasticity required for superior baked goods.

In a bustling bakery, a Knetmaschine might operate continuously throughout the day, turning raw ingredients into tens of kilograms of perfectly kneaded dough ready for proofing and baking.

The impact of Knetmaschinen in the gastronomic field extends beyond efficiency. With their advanced settings and capabilities, they empower chefs and bakers to experiment with a variety of dough types. From traditional sourdough to innovative specialty breads and pastries, these machines facilitate experimentation by offering consistent results. As the culinary world continually evolves, maintaining a balance between speed, efficiency, and quality is crucial. Knetmaschinen provide this balance, enabling gastronomic establishments to keep pace with changing trends and consumer demands without compromising on quality or originality.

Always clean your Knetmaschine thoroughly after each use to maintain hygiene and prolong its lifespan, especially when used in a professional kitchen setting.

Knetmaschine - Key takeaways

- Knetmaschine Definition: A mechanical device used for kneading, mixing, and blending dough in bakeries and culinary settings.

- Knetmaschine Technik: Features include motor power up to 2 horsepower, multiple speed settings, programmable timers, and specialized dough hook designs.

- Knetmaschine Anwendung in der Gastronomie: Essential in large-scale dough preparation, allowing for uniform mixing and efficiency in bakeries and culinary schools.

- Teig Knetmaschine for Brotteig: Automates the dough kneading process, ensuring consistent texture and elasticity for bread dough.

- Knetmaschine Bedienung: Offers programmable settings for precise kneading times and speeds, crucial for high-volume production.

- Importance of Maintenance: Regular cleaning and upkeep extends the lifespan of the Knetmaschine and ensures consistent performance.

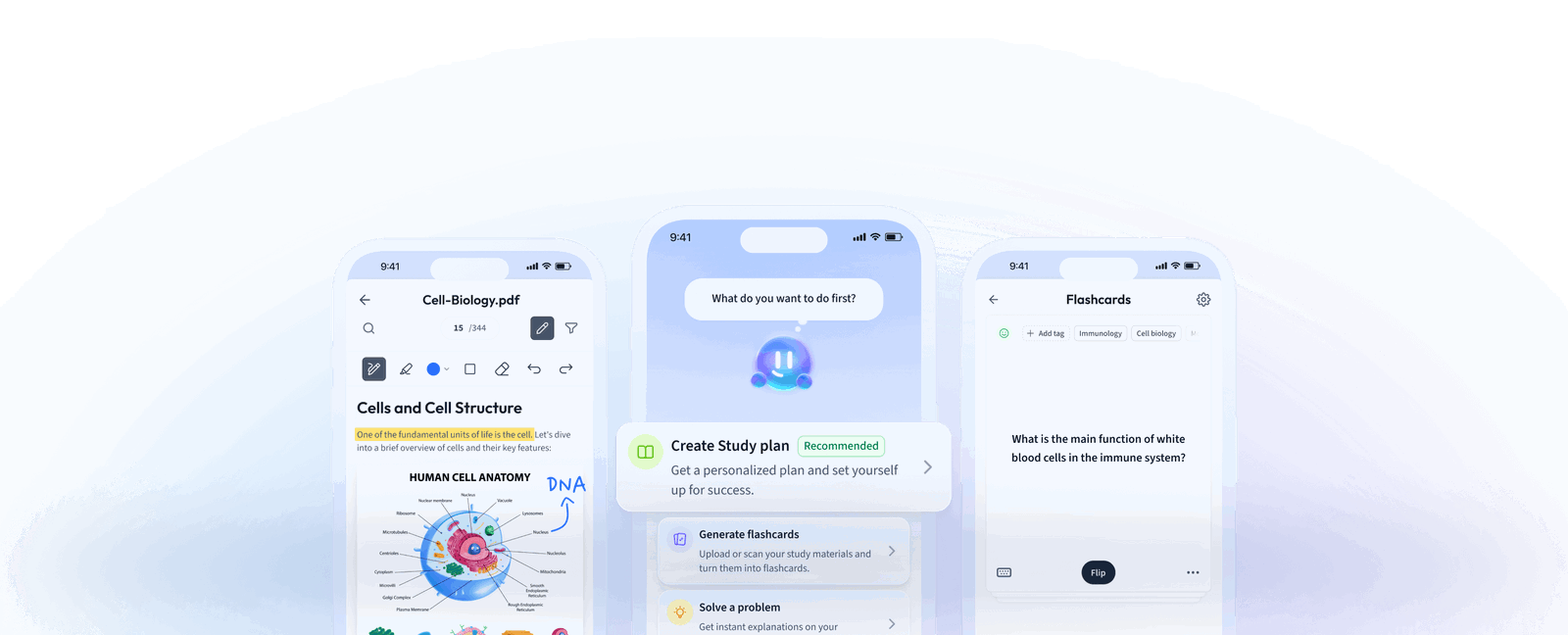

Lerne schneller mit den 12 Karteikarten zu Knetmaschine

Melde dich kostenlos an, um Zugriff auf all unsere Karteikarten zu erhalten.

Häufig gestellte Fragen zum Thema Knetmaschine

Über StudySmarter

StudySmarter ist ein weltweit anerkanntes Bildungstechnologie-Unternehmen, das eine ganzheitliche Lernplattform für Schüler und Studenten aller Altersstufen und Bildungsniveaus bietet. Unsere Plattform unterstützt das Lernen in einer breiten Palette von Fächern, einschließlich MINT, Sozialwissenschaften und Sprachen, und hilft den Schülern auch, weltweit verschiedene Tests und Prüfungen wie GCSE, A Level, SAT, ACT, Abitur und mehr erfolgreich zu meistern. Wir bieten eine umfangreiche Bibliothek von Lernmaterialien, einschließlich interaktiver Karteikarten, umfassender Lehrbuchlösungen und detaillierter Erklärungen. Die fortschrittliche Technologie und Werkzeuge, die wir zur Verfügung stellen, helfen Schülern, ihre eigenen Lernmaterialien zu erstellen. Die Inhalte von StudySmarter sind nicht nur von Experten geprüft, sondern werden auch regelmäßig aktualisiert, um Genauigkeit und Relevanz zu gewährleisten.

Erfahre mehr